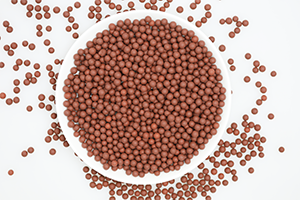

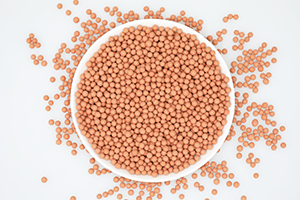

Calcium sulfate Ceramic Balls for Water Filters Efficient Chlorine Removal

Technical Highlights

- 99%+ purity for ultra-fast reaction

- High efficiency even at 0–100°C water temperatures

- Longer-lasting than activated carbon—fewer replacements needed

- Improves water taste—ideal for pre-drinking filtration

- Long-lasting performance—months of use with one application

ETERNAL WORLD Calcium sulfate Ceramic Balls for Water Filters Efficient Chlorine Removal Long Lasting Performance

Core Functional Copy

Efficient Dechlorination, Instant Purification

Made from high-purity calcium sulfite, instantly removes residual chlorine in tap water to ensure safe water for every use.

No Additives, No Residue

100% physical reaction—no added chemicals, no by-products, for cleaner and safer water.

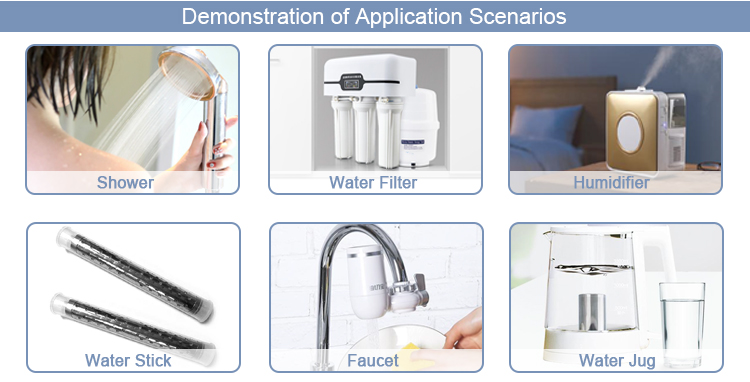

Heat-Resistant & Versatile

Maintains high dechlorination performance even in hot water; ideal for kitchens, showers, laundry, and more.

Dense Structure, Stable Release

Precision-fired ceramic ensures longer-lasting and more consistent dechlorination.

Eco-Friendly Alternative to Traditional Filters

Non-toxic, biodegradable, and a sustainable upgrade from activated carbon and sodium sulfite materials.

Technical Highlights

- 99%+ purity for ultra-fast reaction

- High efficiency even at 0–100°C water temperatures

- Longer-lasting than activated carbon—fewer replacements needed

- Improves water taste—ideal for pre-drinking filtration

- Long-lasting performance—months of use with one application

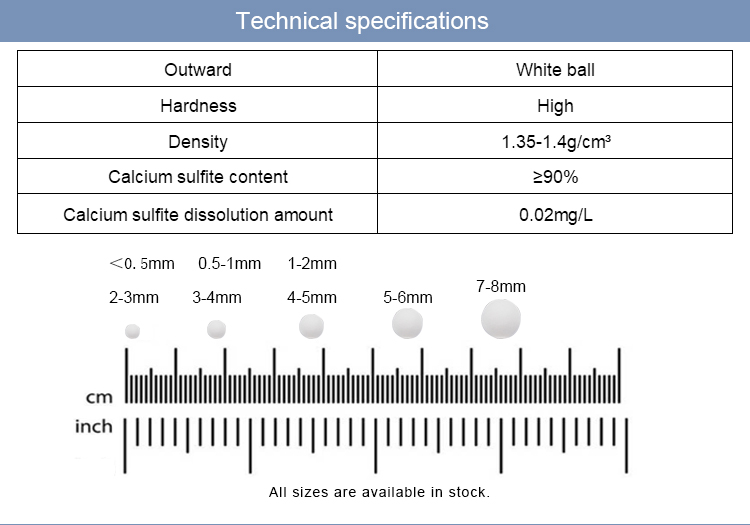

| Test Conditions: Filter Media:CaSO3 Ceramic Balls 0.6-1mm Quantity: 40g Test Conditions: (Tap Water) Inlet Chlorine 2ppm. Water Temperature 40℃. Flow Rate: 7.5L/min Test date: Dec. 19th, 2025 | |||

Filtered Capacity (Litre) | chlorine before filtration (ppm) | chlorine after filtration (ppm) | Chlorine Removal Rate |

| 500 | 2.15 | 0.02 | 99% |

| 1000 | 2.04 | 0.02 | 99% |

| 1500 | 2.1 | 0.04 | 98% |

| 2000 | 2.1 | 0.04 | 98% |

| 2500 | 2.02 | 0.04 | 98% |

| 3000 | 1.99 | 0.1 | 95% |

| 3250 | 2.01 | 0.35 | 83% |

| 3550 | 1.98 | 0.59 | 70% |

| 4000 | 2.09 | 0.69 | 67% |

| 4500 | 2.03 | 0.87 | 57% |

Vacuum package.

Vacuum Packaging for Guaranteed Performance Stability

To make sure that our calcium sulfite dechlorination ceramic balls preserve their chlorine elimination effectivity and bodily integrity for the duration of storage and transportation, we make use of industrial-grade vacuum packaging technology. This method successfully isolates the product from air and moisture, stopping any degradation in overall performance over time.

Brief Introduction:

The Chlorine Reduction Ceramic Balls, additionally recognized as CaSO3 Calcium Sulfite Ceramic Balls, has a great chlorine casting off effect. It is extensively used in a range of dechlorane units such as bathe filters, bathtub filters, swimming pools, bathtub facilities and etc.

Its predominant characteristic is to take away residual chlorine from water, consisting of mixed residual chlorine and free residual chlorine:

Reaction with Chlorine Gas (Cl₂)

Chlorine hydrolyzes in water to structure hydrochloric acid (HCl) and hypochlorous acid (HClO). Calcium sulfite reduces Cl₂ to chloride ions (Cl⁻) whilst being oxidized to calcium sulfate (CaSO₄):

CaSO3+Cl2+H2O→CaSO4+2HClCaSO3+Cl2+H2O→CaSO4+2HCl

Ionic Equation:

SO32−+Cl2+H2O→SO42−+2H++2Cl−SO32−+Cl2+H2O→SO42−+2H++2Cl−

Compared to typical activated carbon for dechlorination, calcium sulfite ceramic balls provide blessings such as long-lasting, excessive efficient, safe, high-temperature resistance, and no bacterial growth. In assessment with KDF copper-zinc alloy, it has a decrease manufacturing fee and greater advantageous in getting rid of chlorine.

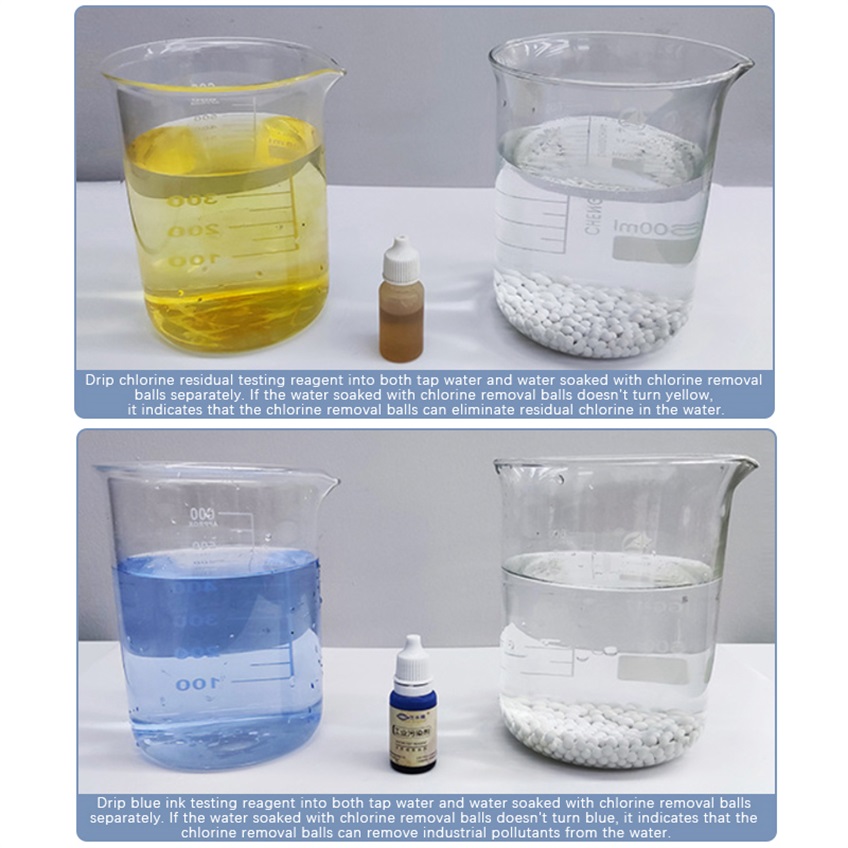

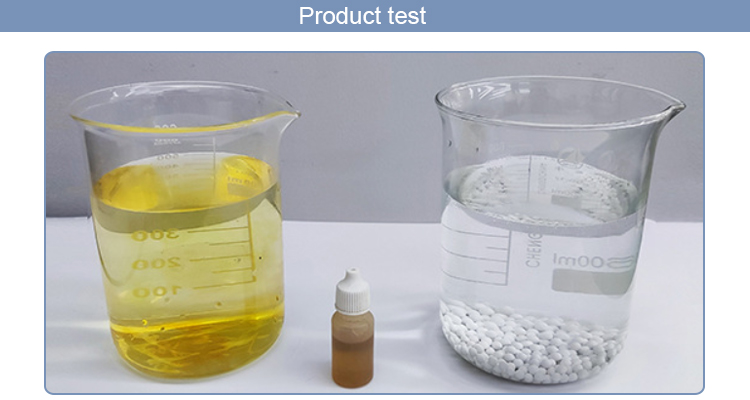

Add a residual chlorine check reagent to each faucet water and water soaked with dechlorination balls. If the water soaked with dechlorination balls does now not flip yellow, it shows that the dechlorination balls can correctly get rid of the residual chlorine from the water.

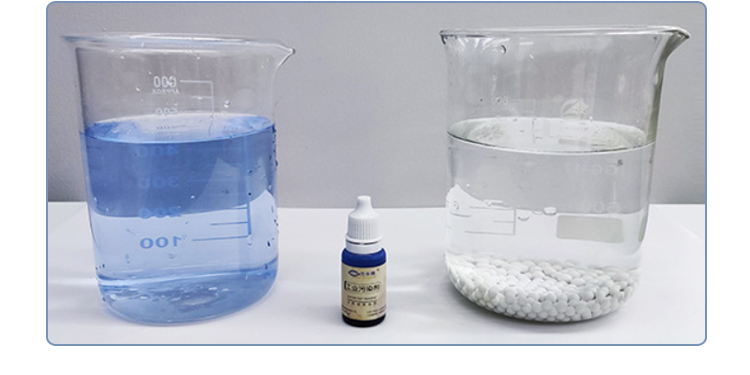

Add blue ink reagent to both tap water and water soaked with dechlorination balls. If the water soaked with dechlorination balls does not turn blue, it indicates that the dechlorination balls can effectively remove industrial pollutants from the water.