2.High-Efficiency Chlorine Removal

Rapid and complete reaction with chlorine (Cl₂) and hypochlorous acid (HClO), achieving 99% above efficacy with minimal dosage.

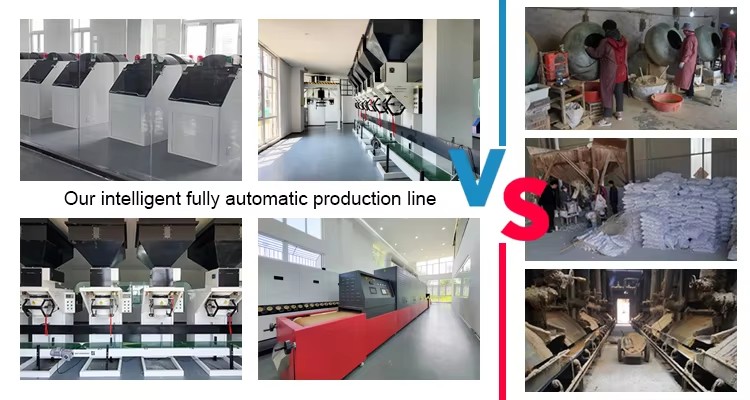

3.Stable & Reliable Quality

Batch-to-batch uniformity with strict control over purity (>90%), particle size, and reactivity for predictable performance.

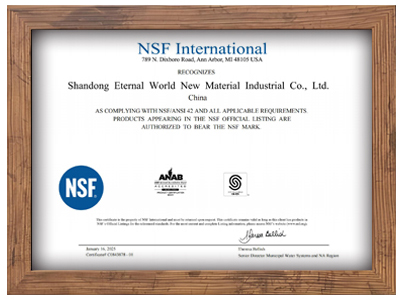

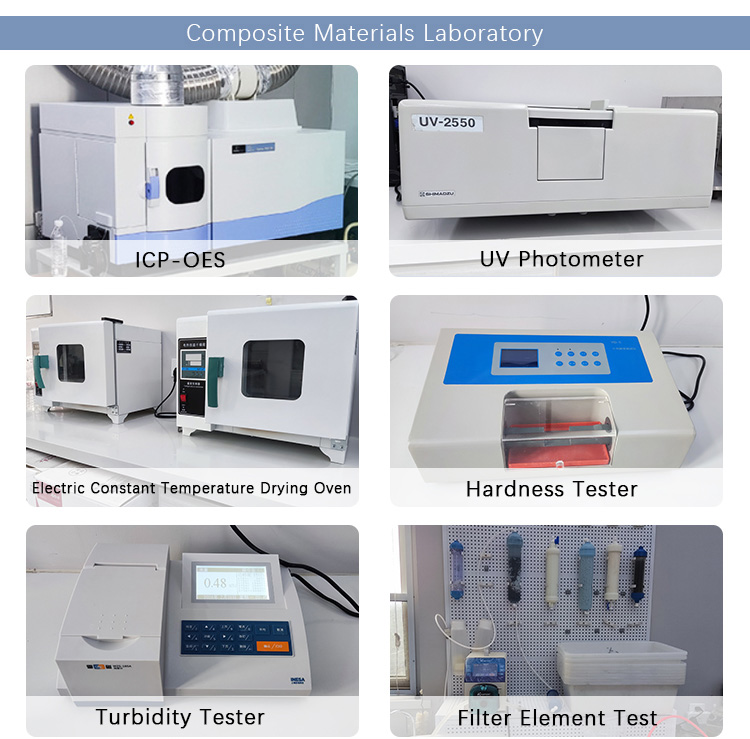

4.Rigorous QC Testing

Every production lot undergoes multi-stage inspections to meet NSF 177 standards.

5.Data-Backed Performance

Tested and verified by our own lab, 3rd party lab tests and customer trials:

i.>99% chlorine removal at 2 ppm residual Cl₂ with flow rate 7L/Min.

ii.Long-term stability (shelf life: 50g 4000 liters of water).

| Test Conditions: Filter Media: CaSO3 Ceramic Balls 0.6-1mm Quantity: 40g Test Conditions: (Tap Water) Inlet Chlorine 2ppm. Water Temperature 40℃. Flow Rate: 7.5L/min Test date: Dec. 19th, 2025 | |||

Filtered Capacity (Litre) | Chlorine before filtration (ppm) | Chlorine after filtration (ppm) | Chlorine Removal Rate |

| 500 | 2.15 | 0.02 | 99% |

| 1000 | 2.04 | 0.02 | 99% |

| 1500 | 2.1 | 0.04 | 98% |

| 2000 | 2.1 | 0.04 | 98% |

| 2500 | 2.02 | 0.04 | 98% |

| 3000 | 1.99 | 0.1 | 95% |

| 3250 | 2.01 | 0.35 | 83% |

| 3550 | 1.98 | 0.59 | 70% |

| 4000 | 2.09 | 0.69 | 67% |

| 4500 | 2.03 | 0.87 | 57% |

Vacuum package.

Vacuum Packaging for Guaranteed Performance Stability

To ensure that our calcium sulfite dechlorination ceramic balls maintain their chlorine removal efficiency and physical integrity during storage and transportation, we utilize industrial-grade vacuum packaging technology. This process effectively isolates the product from air and moisture, preventing any degradation in performance over time.

Brief Introduction:

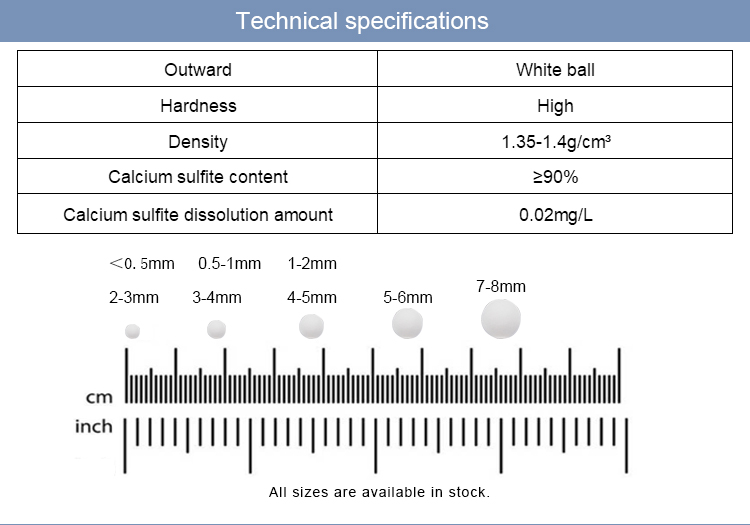

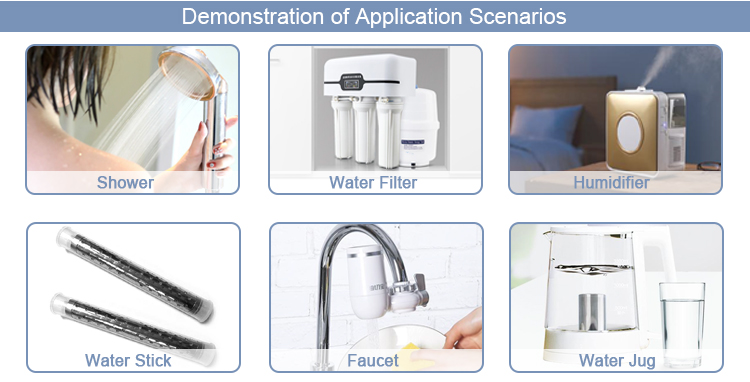

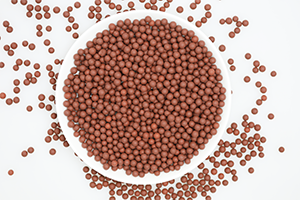

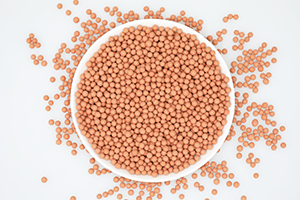

The Chlorine Reduction Ceramic Balls, also known as CaSO3 Calcium Sulfite Ceramic Balls, has a significant chlorine removing effect. It is widely used in various dechlorane devices such as shower filters, bath filters, swimming pools, bath centers and etc. Its main function is to remove residual chlorine from water, including combined residual chlorine and free residual chlorine:

Reaction with Chlorine Gas (Cl₂)

Chlorine hydrolyzes in water to form hydrochloric acid (HCl) and hypochlorous acid (HClO). Calcium sulfite reduces Cl₂ to chloride ions (Cl⁻) while being oxidized to calcium sulfate (CaSO₄):

CaSO3+Cl2+H2O→CaSO4+2HClCaSO3+Cl2+H2O→CaSO4+2HCl

Ionic Equation:

SO32−+Cl2+H2O→SO42−+2H++2Cl−SO32−+Cl2+H2O→SO42−+2H++2Cl−

Compared to traditional activated carbon for dechlorination, calcium sulfite ceramic balls offer advantages such as long-lasting, high efficient, safe, high-temperature resistance, and no bacterial growth. In comparison with KDF copper-zinc alloy, it has a lower production cost and more effective in removing chlorine.

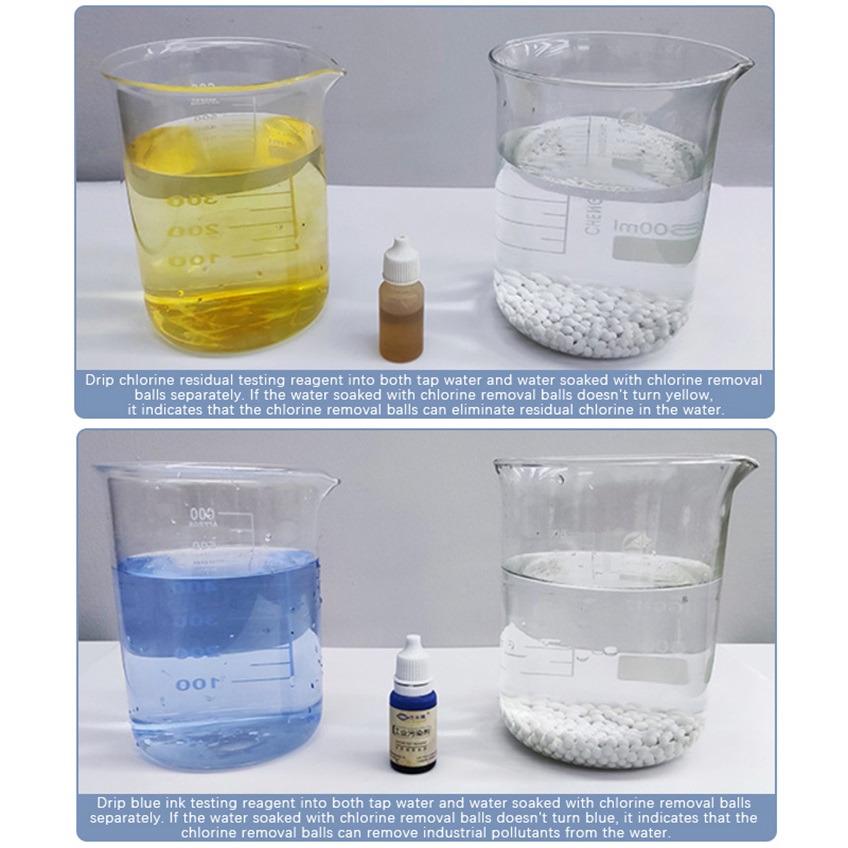

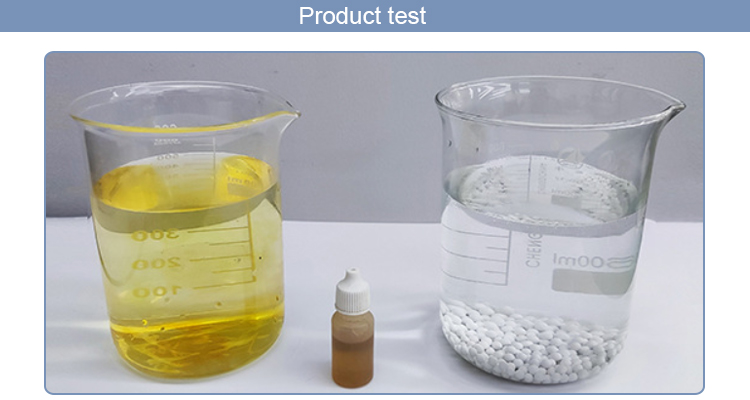

Add a residual chlorine test reagent to both tap water and water soaked with dechlorination balls. If the water soaked with dechlorination balls does not turn yellow, it indicates that the dechlorination balls can effectively remove the residual chlorine from the water.

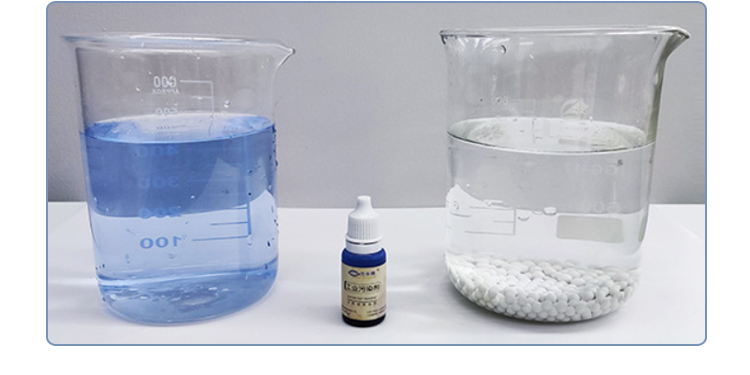

Add blue ink reagent to both tap water and water soaked with dechlorination balls. If the water soaked with dechlorination balls does not turn blue, it indicates that the dechlorination balls can effectively remove industrial pollutants from the water.

Different package designs are available for customers needs.